Products Description

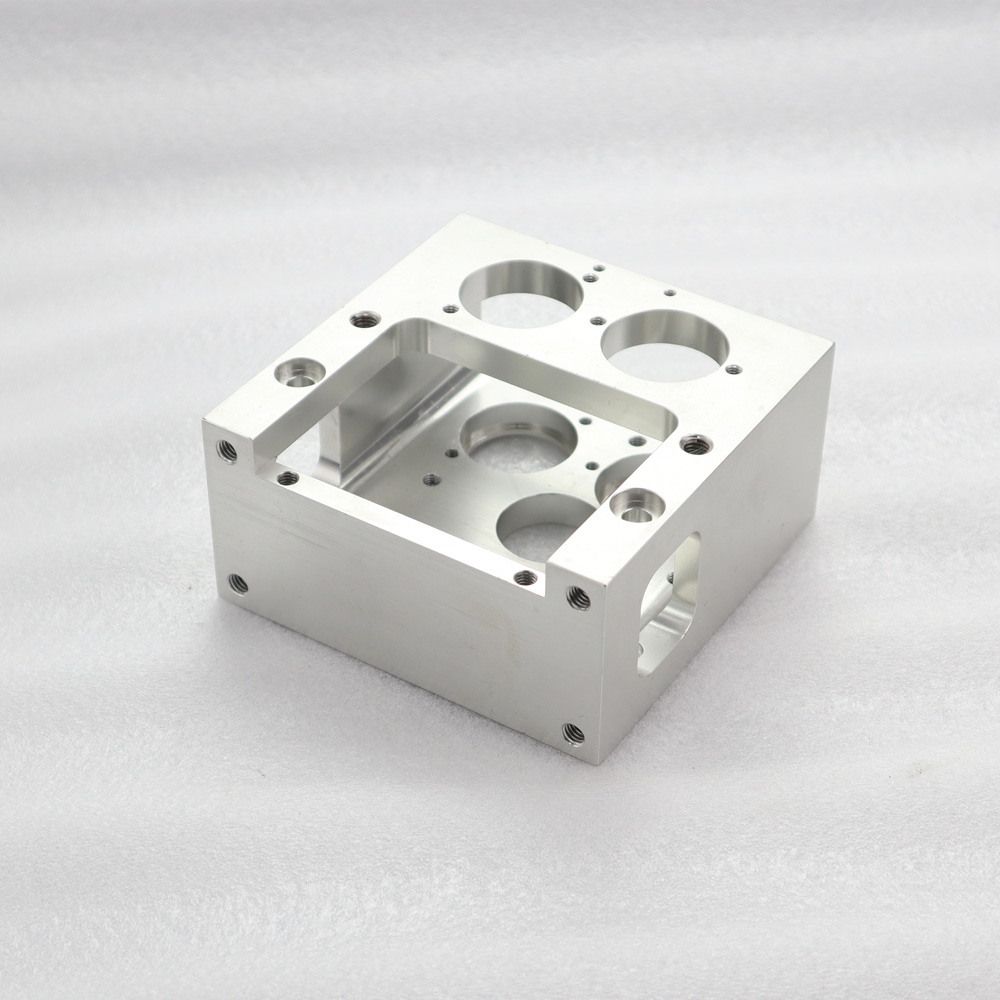

Product Name: Silver Rectangular Metal Connector

Product Overview

This product is a silver-colored rectangular metal component with a mirror-polished finish (Ra ≤0.8μm), presenting a precision industrial texture. The main body features a regular rectangular design with a rectangular groove on the upper side, surrounded by multiple circular holes and screw holes. The lower section contains two larger circular holes (diameter Φ8–Φ12mm) encircled by smaller holes. Mounted on a pure white background, the compact design highlights its simplicity and precision, making it suitable for mechanical assembly, equipment fixation, or structural connection applications.

Core Parameters

| Parameter | Technical Specifications |

|---|---|

| Material | Stainless Steel 304 (Estimated) or Aluminum Alloy 6061 |

| Dimensions | Total length ≈120mm × Width 60mm × Height 40mm (Estimated) Upper groove: 40mm (L) × 10mm (W) Lower main hole diameter: Φ8–Φ12mm |

| Structure | Rectangular body + Upper rectangular groove + Circular holes (Φ3–Φ10mm) + Lower large holes (Φ8–Φ12mm) |

| Surface Finish | Mirror polishing (Ra ≤0.8μm) |

| Load Capacity | Static load ≥20kg (ISO 6055 standard) |

Design Highlights

Functional Structural Design

- Upper Groove: Compatible with rail or buckle installation (friction coefficient μ ≥0.5), enhancing positioning accuracy.

- Circular Holes:

- Φ3–Φ10mm holes on the perimeter for sensor mounting or pipeline fixation.

- Φ8–Φ12mm main holes support bolt or pin fixation (shear strength ≥10kg).

- Screw Hole Layout: Standardized holes (M4–M6) compatible with automated assembly lines.

Material & Process Compatibility

- Stainless Steel 304: High corrosion resistance (salt spray test ≥500 hours), ideal for humid environments.

- Mirror Polishing: Reduces friction coefficient (μ ≤0.12), minimizes assembly scratches, and enhances industrial aesthetics.

Mechanical Optimization

- Hole edges feature R0.3mm fillet transitions to reduce stress concentration and extend service life.

Application Scenarios

| Industry | Typical Use Cases |

|---|---|

| Industrial Equipment | Machine tool fixture positioning / Hydraulic valve brackets |

| Automation Machinery | Robotic arm joint interfaces / Sensor mounting bases |

| Automotive Components | Transmission housing fasteners / Cooling system piping |

Customization Services

✅ Supported Customizations:

- Adjust groove dimensions, hole distribution, or hole diameter specifications (requires 3D model in STEP format).

- Material upgrades (e.g., titanium alloy Ti-6Al-4V for high-stress applications).

- Surface treatment customization (sandblasting/anodizing/brushed texture).

⚠️ Requirements:

- 3D models and tolerance documents (ISO 2768 standard) required.

Technical Support

Tel: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html

Note: All parameters comply with ISO 9001 standards. Free DFM analysis provided.