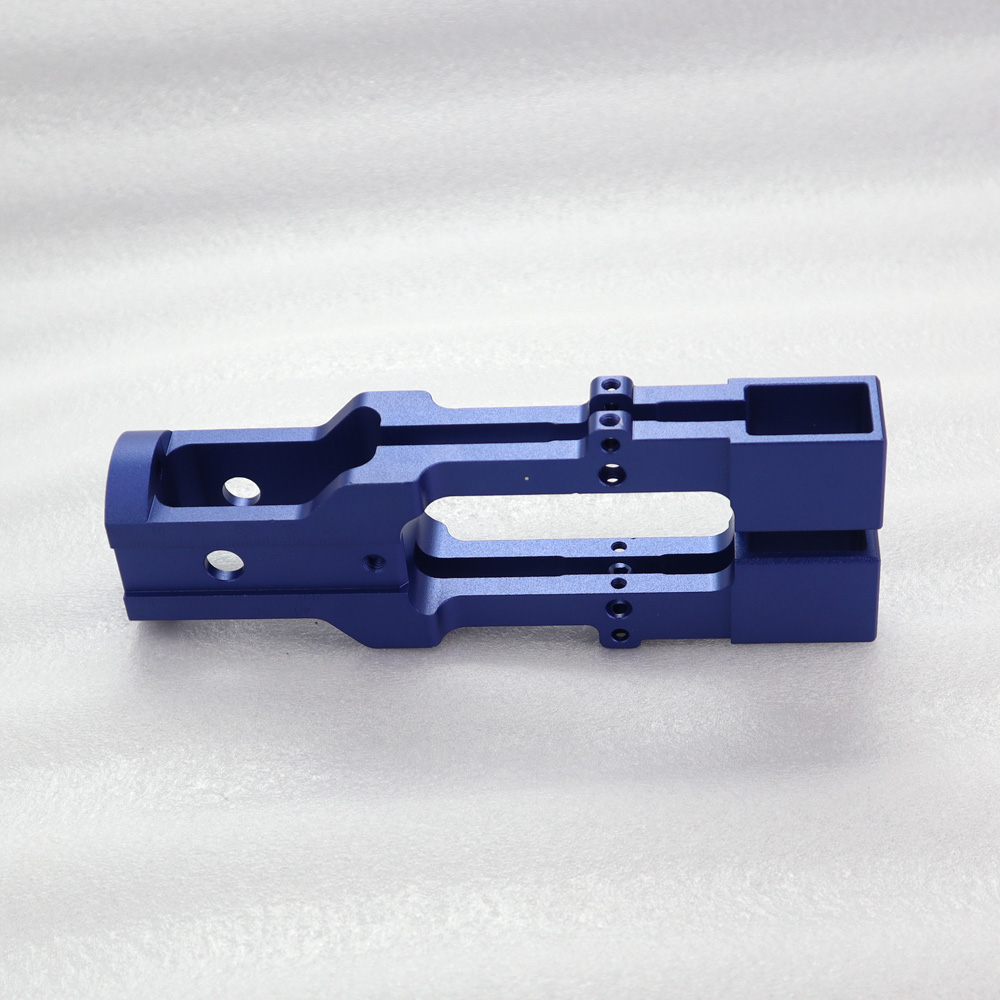

Products Description

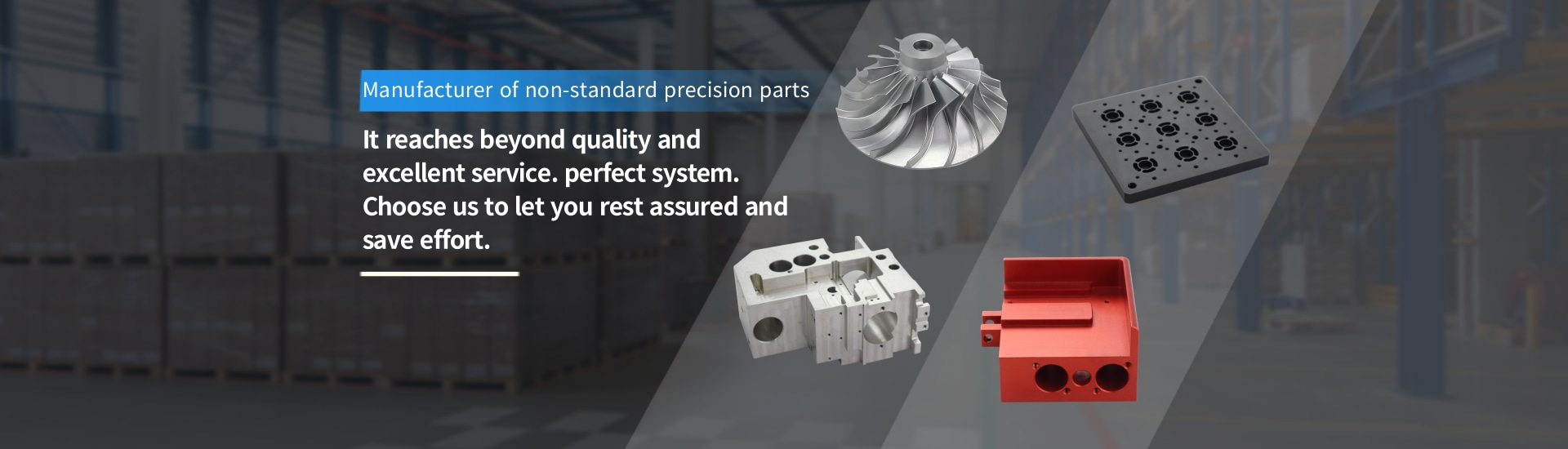

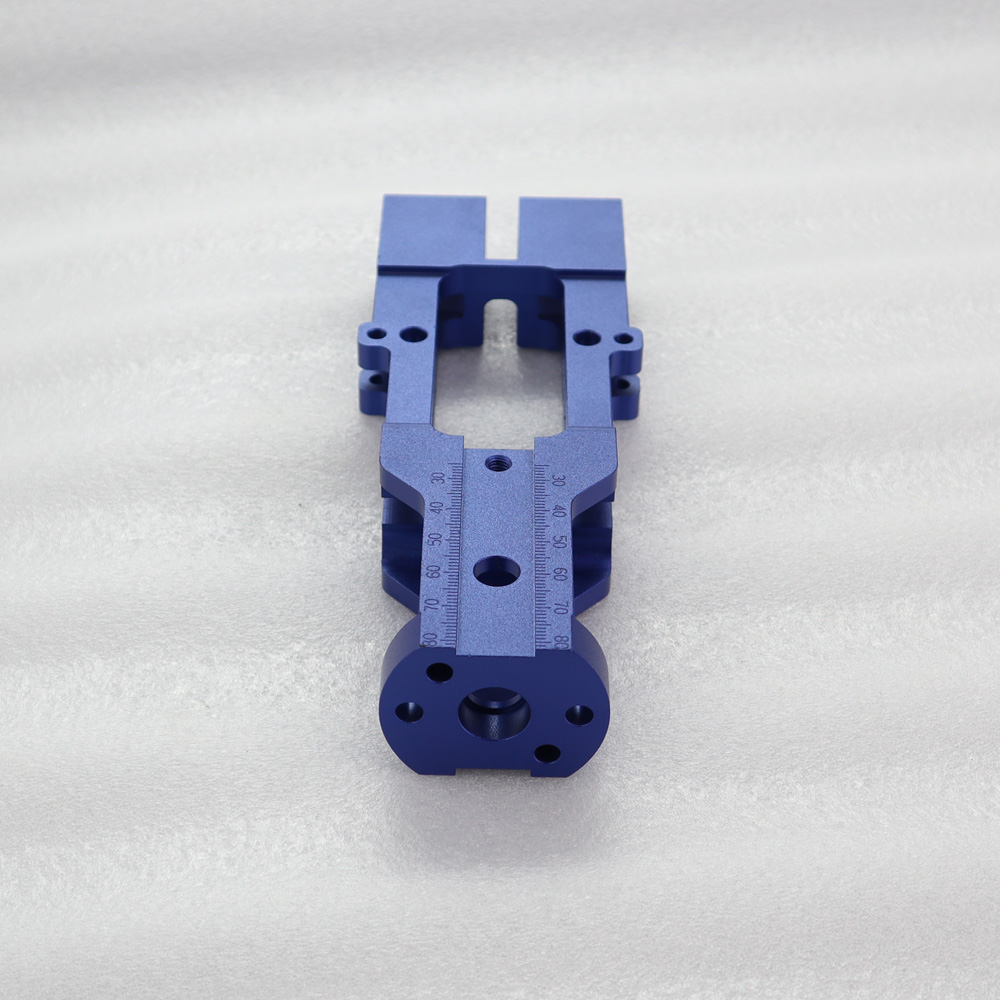

Product Name: Blue Elongated Industrial Measurement Metal Component

Product Overview

This product is a blue metallic elongated component with industrial-grade surface treatment. The main body features a straight design with repeated scale markings (30–80) in the central section for measurement purposes. One end has a rectangular profile, while the other end is circular with integrated holes. The surface includes multiple circular and raised structures, mounted on a light-gray flat background to highlight its precision measurement and industrial assembly functionality. Suitable for mechanical machining, equipment positioning, or engineering measurement applications.

Core Parameters

| Parameter | Technical Specifications |

|---|---|

| Material | Stainless Steel 304 (Suspected) or Aluminum Alloy 6061 |

| Dimensions | Total length ≈200mm × Width 20mm × Thickness 8mm Scale range: 30–80 (dual scale lines) |

| Structure | Elongated body + Dual-end differentiated design (rectangular/circular) + Multiple holes (Φ3–Φ6mm) + Scale markings |

| Surface Finish | Mirror polishing (Ra ≤0.8μm) |

| Load Capacity | Static load ≥15kg (ISO 6055 standard) |

Design Highlights

Functional Structural Design

- Dual-End Differentiated Design:

- Rectangular End: Compatible with standard fixtures or rail mounting (flat area: 10×20mm).

- Circular End: Φ8mm hole supports shaft pins or bolt fixation (shear strength ≥10kg).

- Scale Markings: Dual-scale lines (30–80) enable bidirectional measurement/positioning with ±0.5mm accuracy.

- Holes and Raised Structures: Φ3–Φ6mm holes for sensor installation or pipeline fixation; raised patterns enhance anti-slip performance (friction coefficient μ ≥0.5).

Material and Process Compatibility

- Stainless Steel 304: High corrosion resistance (salt spray test ≥500 hours), ideal for humid environments. Aluminum Alloy 6061 version available for lightweight (density 0.9g/cm³).

- Mirror Polishing: Reduces friction coefficient (μ ≤0.12), minimizes assembly scratches, and enhances industrial aesthetics.

Measurement and Assembly Optimization

- Scale lines laser-engraved with 0.2mm depth for long-term clarity.

- Symmetrical reinforcement ribs on circular and rectangular ends improve bending strength by 20%.

Application Scenarios

| Industry | Typical Use Cases |

|---|---|

| Industrial Equipment | Machine tool fixture positioning / Gauge calibration base |

| Automation Machinery | Robotic arm motion calibration / Sensor mounting brackets |

| Automotive Components | Engine part measurement reference / Transmission housing positioning |

Customization Services

✅ Supported Customizations:

- Adjust scale range, end shapes, or hole distribution (requires 3D model in STEP format).

- Material upgrades (e.g., titanium alloy Ti-6Al-4V for high-stress applications).

- Surface treatment customization (sandblasting/anodizing/satin texture).

⚠️ Requirements:

- 3D models and tolerance documents (ISO 2768 standard) required.

Technical Support

Tel: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html

Note: All parameters comply with ISO 9001 standards. Free DFM analysis provided.