Products Description

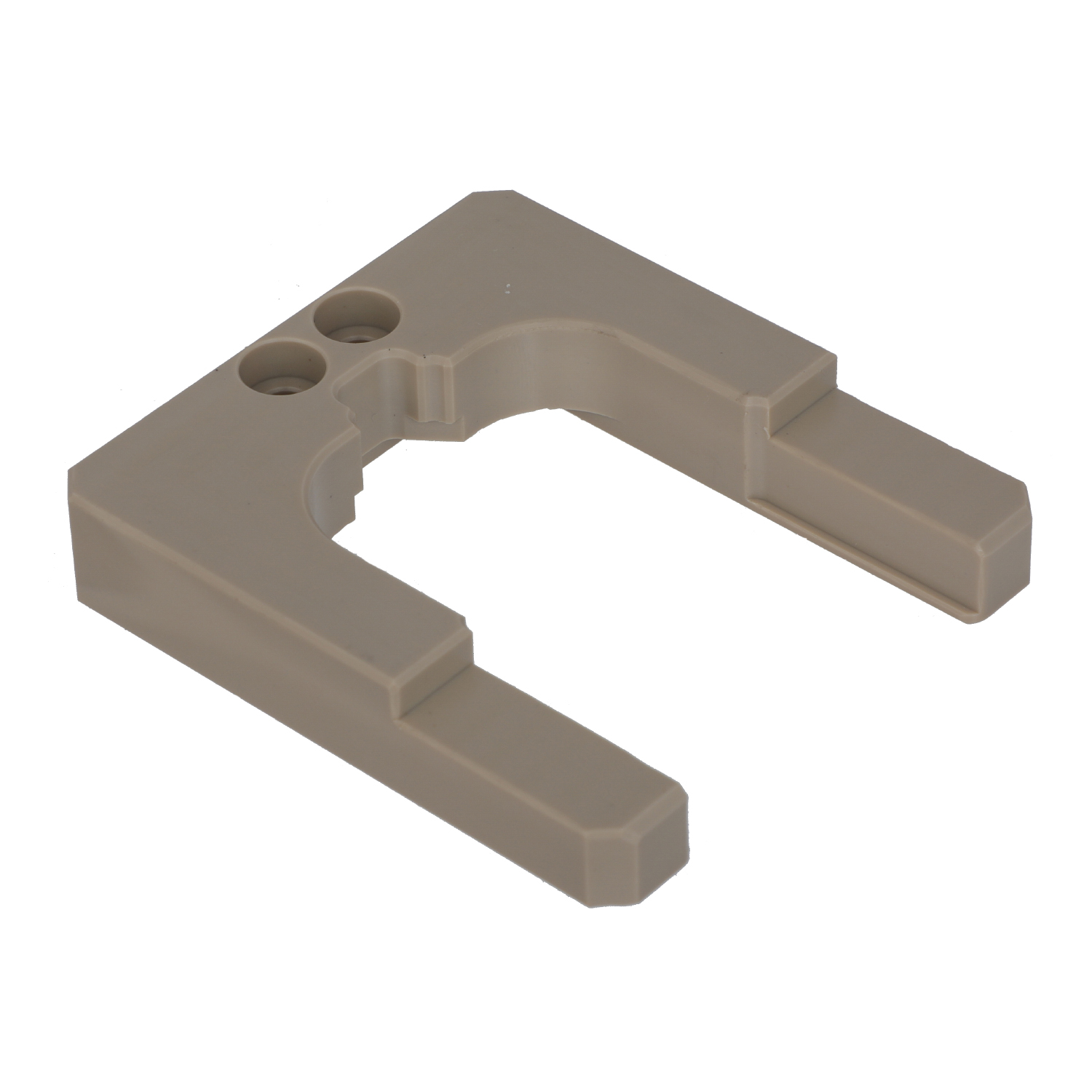

Product Name: Light Brown Industrial Frame Plastic Structural Component

Product Overview

This product is a light brown rectangular plastic frame component with an approximate "U"-shaped open design. The right vertical surface features two threaded circular holes. The material is speculated to be polypropylene (PP) or ABS engineering plastic, with a matte finish (Ra ≤1.6μm) for an industrial-style, non-slip texture. Suitable for mechanical support, equipment fixation, or home organization applications.

Core Parameters

| Parameter | Technical Specifications |

|---|---|

| Material | Polypropylene (PP) or ABS (Estimated) |

| Dimensions | Total length ~80mm × Width 50mm × Height 30mm |

| Structural Features | "U"-shaped opening (smooth edges) + dual threaded holes |

| Surface Finish | Matte texture (Ra ≤1.6μm) |

| Load Capacity | Static load ≥8kg (ISO 6055 standard) |

Design Highlights

Functional Structural Design

- "U"-shaped Opening: Compatible with standard rails or buckle installations (width 40–60mm), smooth edges minimize scratching risks.

- Threaded Hole Layout: Two Φ6mm holes (spaced 20mm apart) on the right side support M6 countersunk screws, shear strength ≥10kg.

Material & Process Compatibility

- Material Selection: PP offers lightweight (density 0.9g/cm³) and chemical corrosion resistance; ABS version available for enhanced impact resistance.

- Surface Treatment: Matte finish (Ra ≤1.6μm) improves anti-slip properties; optional anodizing (ABS) enhances wear resistance.

Assembly Compatibility

- The inner frame accommodates standard aluminum profiles (50×50mm cross-section) via slots or screws for secondary fixation.

Application Scenarios

| Industry | Typical Use Cases |

|---|---|

| Industrial | Robotic arm rail brackets / Tool cabinet dividers |

| Home Decor | Wall-mounted shelves / Lighting fixture bases |

| Electronics | Equipment enclosure frames / Cable management brackets |

Customization Services

✅ Supported Customizations:

- Provide 3D models (STEP format) to optimize opening dimensions or hole distribution.

- Material upgrades (e.g., nylon PA12 reinforced version).

- Surface treatment customization (sandblasting/UV coating).

⚠️ Requirements:

- 3D models and tolerance documents (ISO 2768 standard) required.

- Complex structures may incur mold development fees (¥1,500–3,000).

Technical Support

Tel: +86 150-1532-6863

Email: cassy@xqdmachining.com

Website: https://xqdmachining.com/index.html

All parameters comply with ISO 9001 standards. Free DFM analysis provided.

Key Analysis Notes

- Material Inference: Light brown appearance suits PP/ABS; PP offers lower cost, ABS provides higher impact resistance.

- Process Adaptability: Matte treatment meets anti-slip needs; ±0.1mm hole tolerance ensures screw reliability.

- Application Flexibility: Frame structure supports secondary processing (e.g., drilling/tapping) for multi-scenario reuse.