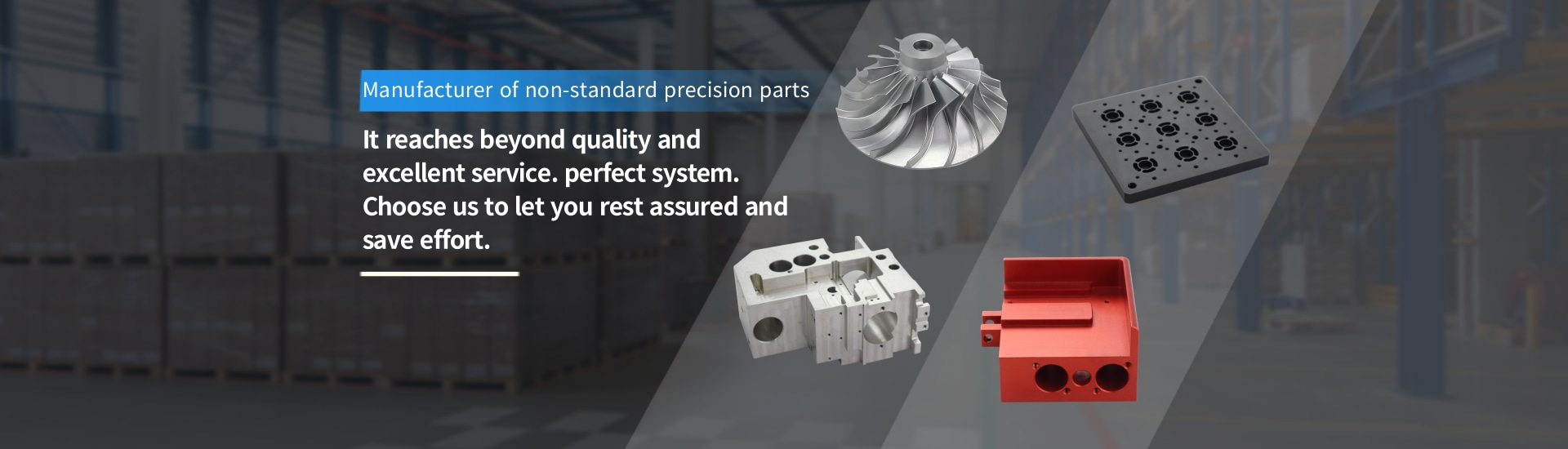

5-Axis CNC Machining: The Definitive Solution for Turbocharger Impeller Fabrication

Precision Engineering for Extreme Performance

1. Technical Evolution in Turbomachinery

1.1 Industry Demands

- Sub-micron Precision Requirements

- Blade twist angles: 12°–35° (aerodynamic optimization)

- Thermal stability: >900°C operational temperatures (Inconel 718)

- Conflict Resolution

- Thin-wall structures (<0.8mm shroud thickness)

- Complex curvature radii (<2mm)

1.2 Traditional 3-Axis Limitations

| Limitation | Impact |

|---|

| Setup complexity | 8–12 repositioning steps/impeller |

| Material waste | 30–40% due to inaccessible regions |

| Cumulative errors | ±0.05mm positional deviation |

2. 5-Axis Machining Technology Breakthrough

2.1 Kinematic Advantages

- Simultaneous Motion Control

- X/Y/Z linear + A/B rotary axes synchronization

- Helical interpolation for blade root blending (transition radius<0.1mm)

- Toolpath Optimization

- Trochoidal Milling:

- 3D spiral paths reduce cutting forces by 40%

- Adaptive clearance angles (3°–15° anti-chatter)

- Single-Setup Machining

- Fixtureless clamping (±0.005mm repeatability)

- Thermal compensation algorithms (±2μm stability)

2.2 Performance Comparison

| Parameter | 5-Axis Machining | Traditional 3-Axis |

|---|

| Setup time | 30% reduction | 8–12 steps |

| Surface roughness (Ra) | 0.1–0.4μm | 0.8–1.6μm |

| Tool life | 300% extension | Standard carbide tools |

3. Precision Solutions for Critical Challenges

3.1 Thin-Wall Machining Protocol

- Vortex Suppression

- High-pressure coolant injection (1000–1500 psi)

- Chip formation stabilization

- Tool Engineering

- Diamond-coated carbide (10° negative rake angle)

- Tool life extension: 300%

- Real-Time Compensation

- In-process metrology for deformation monitoring

3.2 Surface Finish Enhancement

- Multi-Stage Process

- Roughing (Ra 3.2μm)

- Semi-finishing (Ra 1.6μm)

- Spark-assisted polishing (Ra<0.4μm)

- Non-Contact Inspection

- Confocal chromatic sensors (3D topography mapping)

3.3 Dynamic Balance Assurance

- In-Process Correction

- Real-time balancing during finish machining

- Modal Analysis

- FEA modeling of first 10 vibration modes

4. Case Study: Marine Turbocharger Impeller

4.1 Technical Requirements

| Specification | Parameters |

|---|

| Diameter | 52 inches |

| Material | Ti-6Al-4V (880MPa yield) |

| Tolerance | ±0.02mm concentricity |

| Blade Geometry | 18 backward-curved blades |

4.2 Machining Workflow

- Hybrid Process

- 5-axis roughing (12 cm³/min material removal)

- Electrochemical finishing (Ra 0.1μm)

- Quality Control

- CMM inspection every 3 hours (SPC control)

- CNC offset updates via real-time data

4.3 Performance Results

| Metric | Achieved | Industry Standard |

|---|

| Cycle time | 45% reduction | 8–10 hours |

| First-article pass rate | 98.7% | 85–90% |

| Turbine efficiency gain | 300% (ISO conditions) | 50–100% typical |

5. Runsom Precision’s Technology Ecosystem

5.1 Manufacturing Infrastructure

- Machinery

- DMG MORI NTX 5-axis (12,000rpm spindles)

- Zeiss Calypso metrology (0.5μm resolution)

- Software

- Siemens NX with turbomachinery post-processors

5.2 Value-Added Services

- Design Support

- Free CFD simulations for DFM optimization

- Cost Reduction

- Material substitution recommendations (e.g., Inconel 625 vs. 718)

- Turnkey Solutions

- On-site assembly and dynamic balancing

6. Actionable Next Steps

- Submit 3D Model

- Upload to XINQIDA Turbocharger Portal

- Receive automated manufacturability analysis

- Get Custom Quote

- Comparative 5-axis vs. 3+2 axis cost analysis

- Lead time estimation within 24 hours

- Technical Consultation

- Contact materials science experts: +86 15015326863